COMMON LEAF SPRING PROBLEMS AND SOLUTIONS

Although leaf springs are among the most durable and time-tested suspension components, they are not immune to problems - especially after years of intensive use, overloading, or poor road conditions. When issues arise, they can significantly affect both vehicle safety and driving comfort.

Some of the most common problems include:

-

Cracks or complete spring breakage, often leading to unsafe axle positioning

-

Weak or sagging springs, causing the vehicle to sit lower and handle poorly

-

Increased body sway during cornering or braking, especially under load

-

Worn or noisy spring assemblies, leading to squeaking, rattling, or clunking sounds

These symptoms should never be ignored. Even a partially damaged spring can compromise vehicle control and accelerate the wear of other suspension components.

In the following sections, we'll explore each of these issues in detail - including their causes, consequences, and how they can be prevented or resolved.

Why do leaf springs break?

Understanding the root causes of leaf spring failure helps prevent future problems and ensures proper maintenance practices.

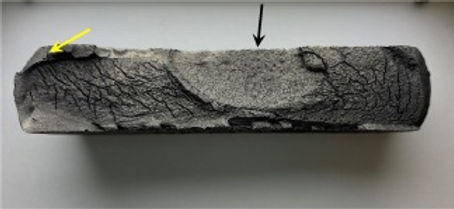

Surface microcracks

Tiny cracks may form on the surface of a spring due to manufacturing imperfections or mechanical damage during operation. These cracks can be caused by road debris impacts, over-tightening during installation, or stress from poor road conditions. Over time, these microcracks can grow and lead to complete failure.

Nonmetallic inclusions in spring steel

During the steel manufacturing process, nonmetallic inclusions such as oxides or sulfides can become embedded within the spring. These inclusions weaken the material if they are too large or located near the surface, increasing the likelihood of crack formation and eventual fracture.

Improper heat treatment

Leaf springs undergo a precise heat treatment process to achieve optimal hardness, flexibility, and fatigue resistance. The process involves:

-

Heating to 850–950°C

-

Quenching in oil to 45–55°C

-

Tempering at 400–500°C before cooling to room temperature

If this process is not carefully controlled, the result can be a spring that is either too brittle or too soft, both of which increase the risk of breakage under stress.

Surface decarburization

In smaller repair shops or DIY environments, open-flame heating can cause surface decarburization, which means carbon burns out from the steel surface. This weakens the material and can lead to early-stage cracking, especially under high loads.

Corrosion

Rust and corrosion start on the surface and can gradually work their way deeper into the steel. As corrosion progresses, it creates stress risers, which are points where cracks are more likely to initiate and propagate under load.

H3: Failure around the center hole

If U-bolts are not tightened properly, especially after installation or service, the spring can shift or flex unevenly. This can lead to cracking around the center hole of the leaf spring.

Eye breakage

A leaf spring may break at the spring eye due to:

-

Manufacturing defects

-

Excessively worn bushings

-

Corroded or seized spring pins or shackles

Each of these contributes to uneven load distribution and higher localized stress. Many times, when a leaf spring breaks on one side of the vehicle and the vehicle is used for a longer period, the leaf spring eye on the other side gets under tension and might break.

Chronic overloading

Operating a vehicle consistently beyond its designed payload capacity significantly increases stress on the leaf springs. Repeated overloading accelerates fatigue and drastically reduces spring life.

Harsh road conditions

Frequent exposure to rough terrain, potholes, or off-road conditions causes high dynamic loads on the suspension. This repetitive stress accelerates fatigue and increases the chance of failure.

Suboptimal design choices

In some cases, vehicle manufacturers optimize suspension designs to reduce weight and cost, which may compromise durability. If a spring is too thin or too short for the actual operating conditions, it may not withstand the demands of real-world use, especially in commercial fleets.

Final thoughts

If your vehicle's leaf spring has broken, it's rarely the driver's fault. Most failures result from a mix of material fatigue, environmental factors, and long-term usage conditions. However, prompt replacement is essential to restore safety, stability, and load-handling performance.

Is it safe to drive with a broken leaf spring?

Important safety considerations for all vehicles with leaf spring suspension.

Driving with a broken leaf spring can be dangerous, but the level of risk depends on several key factors. Leaf springs play a critical role in securing the axle to the chassis and supporting the vehicle's load. If one breaks, the consequences can range from minor discomfort to complete loss of control.

Here are the six most important questions to consider before deciding whether to keep driving your vehicle with a broken leaf spring:

-

Where exactly did the leaf spring break?

-

Is it a single-leaf spring (mono leaf) or a multi-leaf spring pack?

-

If it's a multi-leaf spring, which specific leaf is broken?

-

Is your vehicle loaded or empty?

-

Does the suspension system include a stabilizer bar?

-

Are you prepared to accept the risk of driving with a compromised suspension component?

The most dangerous case

The most critical failure occurs when a mono leaf spring or the main leaf of a spring pack breaks between the axle and the front eye (fixing point), and the vehicle does not have a stabilizer bar. In this situation, the axle is no longer properly secured to the vehicle frame on that side. The remaining leaf spring on the opposite side must absorb all the forces and may snap under the increased stress. If that happens while driving, the axle can shift out of place, causing a loss of control and potentially leading to an accident.

In such cases, the vehicle should only be moved at minimal speed and taken to a service center immediately. Continuing to drive with a broken main leaf under these conditions is extremely unsafe.

When it might be temporarily acceptable

If the main leaf is not broken, or if the break is located between the axle and the rear eye, or if only one of the secondary leaves in a multi-leaf spring pack is damaged, it may be possible to drive the vehicle for a short time. However, it must not carry heavy loads, and the driver should exercise extreme caution during acceleration, braking, and cornering.

Even in these less critical situations, the broken leaf spring still compromises suspension performance and structural safety. Continuing to drive under load or at high speed can worsen the damage and lead to further mechanical failures.

Can we prevent breakage of leaf springs?

How to extend the life of your leaf spring suspension.

Leaf spring breakage is a serious issue that can lead to unsafe driving conditions, costly repairs, and unplanned vehicle downtime. While no suspension component lasts forever, many causes of leaf spring failure can be minimized—or even prevented—through proper maintenance, careful driving habits, and attention to load limits.

Avoid overloading the vehicle

One of the most common reasons for leaf spring failure is carrying more weight than the suspension was designed for. Repeated overloading causes excessive flexing and accelerates fatigue. Always follow the manufacturer's load capacity guidelines. If your vehicle often operates under heavy loads, consider upgrading to heavy-duty or reinforced leaf springs.

Inspect your suspension regularly

Visual inspections can help catch early warning signs such as:

-

Rust forming on the spring surface

-

Cracked paint or protective coating

-

Misalignment or sagging

-

Broken or missing leaves

Routine inspections allow you to address small issues before they become major problems. Mechanics should also inspect the bushings, shackles, and U-bolts, as worn or loose components can cause uneven stress on the spring.

Avoid poor road conditions when possible

Driving frequently on rough terrain, pothole-filled roads, or construction zones increases the risk of leaf spring fatigue and breakage. If you can't avoid bad roads, drive more slowly and smoothly to reduce impact forces on the suspension.

Clean off road salt and mud

Salt, mud, and debris can build up between the leaves and speed up corrosion, especially in cold climates. Regularly cleaning your undercarriage helps preserve the life of the steel. For extra protection, consider anti-rust treatments or spring liners that reduce friction and isolate moisture.

Maintain proper U-bolt torque

Loose or uneven U-bolt torque allows the axle to shift slightly during movement, causing the center bolt and spring pack to take uneven loads. After installing a new leaf spring, it's essential to retighten the U-bolts after 500–1,000 km of driving, as the material may settle.

Avoid makeshift repairs

Never weld or heat-treat broken leaf springs without professional equipment and experience. Poorly done repairs can weaken the material and make it more prone to failure. Always replace damaged springs with high-quality components from trusted suppliers.

Choose quality springs

Not all leaf springs are made to the same standards. High-quality springs are made from carefully alloyed and heat-treated spring steel with strict quality control. Avoid low-cost, low-quality products that may contain harmful inclusions, poor tempering, or uneven material hardness.

Can a broken leaf spring be repaired with welding?

Why welding is not a safe solution for broken leaf springs.

When a leaf spring breaks, many drivers or mechanics wonder if it can be repaired by simply welding the broken pieces back together. While this might seem like a fast and inexpensive fix, welding is NOT a reliable or safe method to restore the structural integrity of a leaf spring.

Why welding doesn't work on spring steel

Leaf springs are made from high-carbon or alloy spring steel, which is specially heat-treated to provide both strength and flexibility. While these steels can technically be welded, the process introduces several serious risks:

-

The heat from welding alters the internal structure of the steel near the weld area

-

The material becomes brittle or too soft in the heat-affected zone

-

The welded section loses its elasticity and fatigue resistance, making it prone to early failure

-

The joint will not match the original steel in mechanical properties or durability

As a result, even if a weld appears strong, it creates a weak point in the spring. In most cases, the spring will break again within weeks, often in the same location or very close to the weld.

No professional manufacturer recommends welding

Leaf spring manufacturers and suspension experts strongly advise against welding broken spring leaves. Professional repair standards require the replacement of damaged components with new, certified spring leaves that meet OEM or aftermarket specifications.

Attempting to weld a leaf spring may not only lead to another failure but can also pose a serious safety risk to the driver and others on the road.

Alternative: replace, don't repair

If a leaf spring is cracked, split, or broken, the only proper and lasting solution is complete replacement. This ensures that the suspension system maintains its original strength, performance, and safety. Replacement leaf springs are relatively affordable, especially when compared to the cost of a breakdown or accident caused by a failed welded spring.

What other problems can occur with leaf springs?

While leaf springs are known for their durability and load-carrying capacity, they are not immune to issues. The most common problems include reduced performance, noise, and ride comfort concerns. Below are the typical issues and their potential solutions:

Sagging or swaying due to weak leaf springs

One of the most frequent issues is that the leaf springs become too weak over time, causing the rear of the vehicle to sag or sway, especially under load. Leaf springs naturally wear out after 5–10 years of use, depending on vehicle type and operating conditions.

Solution: Replace the worn-out leaf springs with new ones.

Underdimensioned springs for heavy-duty applications

Some vehicles suffer from leaf spring weakness due to undersized factory design, particularly when operating at maximum payload or under constant load, such as:

-

Service vehicles with cranes or tail lifts

-

Camper vans or conversions

-

Tradesman vehicles with heavy racking systems

Solutions:

-

Install auxiliary suspension systems (air springs, helper springs)

-

Use leaf spring reinforcement kits

-

Replace the OEM spring with a stronger heavy-duty leaf spring

Premature weakening due to heat treatment defects

In some cases, leaf springs may lose their strength after just a few months. This typically points to production-related defects, most commonly due to incorrect heat treatment or metallurgical inconsistencies during manufacturing.

Solution: Replace the leaf spring. This issue is usually covered under warranty by the spring manufacturer.

Squeaking or creaking noises

Leaf springs may produce squeaking noises during vehicle operation. This can be caused by:

-

Worn-out or missing plastic/rubber interleaf pads

-

Deteriorated or dry leaf spring bushings

-

Corrosion or friction between metal surfaces

Note: In heavy-duty truck leaf springs, a certain level of squeaking may be normal and difficult to eliminate entirely.

Recommendation: A detailed inspection is always needed to identify the exact noise source.

Harsh ride quality when unladen

Leaf spring suspensions are often criticized for delivering a harsh ride, especially when the vehicle is empty or lightly loaded. This is a known trade-off with leaf spring systems—they are optimized for load capacity, not comfort.

Improvement options:

-

Replace the main spring with a softer leaf spring

-

Add a supplementary air spring system for better ride control

Key takeaways

-

Leaf spring failure is usually caused by a combination of material fatigue, environmental factors, and operating conditions

-

Driving with a broken main leaf spring is extremely dangerous and should be avoided

-

Most leaf spring failures can be prevented through regular inspection, proper maintenance, and avoiding overloading

-

Welding broken leaf springs is not a safe or reliable repair method

-

Complete replacement with quality springs is the only proper solution for damaged leaf springs

-

Weak or sagging springs typically need replacement after 5–10 years of use

-

Aftermarket manufacturers often provide stronger alternatives to undersized OEM springs

-

Regular cleaning and corrosion protection significantly extend spring life

-

Proper U-bolt torque maintenance is critical for spring longevity

Related topics

Continue learning - explore these related topics: