TYPES OF LEAF SPRINGS

Leaf springs come in several distinct designs, each optimized for specific applications, load requirements, and performance characteristics. Understanding the differences between conventional, parabolic, and specialized spring types helps you select the right suspension solution for your vehicle and identify which type is currently installed.

This guide covers the main leaf spring categories used in commercial vehicles, pickup trucks, and trailers, explaining their construction, advantages, and typical applications.

Conventional leaf springs (multi-leaf springs)

Conventional leaf springs consist of multiple steel leaves stacked together, each shorter than the one above it. The top leaf, known as the main leaf, usually includes the spring eyes that attach to the chassis, while the rest of the leaves taper toward the center.

Key features

-

Rugged and time-tested design

-

Strong and capable of carrying heavy loads

-

Typically used in construction trucks, trailers and pickups

-

Low manufacturing cost

-

Linear spring rate

Advantages

-

Excellent durability and simplicity

-

Easy to service and replace individual leaves

Disadvantages

-

Higher weight compared to modern alternatives

-

Less comfortable ride due to interleaf friction

Parabolic leaf springs

Parabolic leaf springs are a modern evolution of traditional multi-leaf spring designs, offering a balance between weight reduction, ride comfort, and performance durability. The core idea behind the parabolic spring lies in the variable cross-sectional thickness along the length of the leaf, following a parabolic taper.

What is the technical logic behind the parabolic profile?

Uniform stress distribution: in a conventional spring with constant thickness, the bending stress is concentrated in specific zones, particularly near the center bolt and around the spring eyes. This creates areas of peak tension and increases the risk of fatigue cracks over time.

A parabolic leaf, however, gradually tapers from the center toward the ends, resulting in:

-

More even stress distribution along the length of the spring

-

Lower stress concentration near critical zones

-

Higher fatigue life, even with fewer leaves

This design follows the principle of optimal material usage: more material where bending moments are highest, less where they are minimal.

Variable thickness = variable stiffness

The parabolic profile allows for precise control over the local stiffness of the spring at every point along its length.

-

Thicker center = stiffer core for load-bearing

-

Thinner ends = more flexible zones to absorb shocks and road vibrations

This controlled stiffness profile gives the spring a progressive spring rate, which means:

-

Soft response under light load for better comfort

-

Stiffening response under heavy load for stable handling

Fewer leaves, less interleaf friction

A conventional multi-leaf spring relies on stacking multiple full-contact leaves, which introduces:

-

Interleaf friction (energy loss, heat generation)

-

Creaking noises

-

The need for regular lubrication or liners

Parabolic springs typically use:

-

1 to 5 leaves, each with non-contact zones (separated by spacers or silent blocks)

-

Significantly reduced friction and weight

-

Improved ride comfort and noise reduction

Weight saving

The parabolic profile achieves the same spring rate as a conventional spring with up to 30% less weight. That's because:

-

Material is removed where it's structurally unnecessary

-

The design is optimized for load paths, not for manufacturing simplicity

A typical parabolic spring may consist of up to 5 (sometimes 6) leaves, each independently tapered, instead of a heavy 5-15 leaf conventional pack. And in many cases one parabolic spring leaf makes the job (e.g. LCV leaf springs).

Better dynamic performance

With reduced mass and friction, parabolic springs react faster to dynamic inputs:

-

More efficient energy absorption

-

Better suspension articulation

-

Lower unsprung mass, improving overall vehicle control

This is especially valuable in:

-

Light commercial vehicles (LCVs)

-

Pickup trucks and SUVs

-

Trailers designed for mixed on/off-road use

Main advantage

The biggest benefit of parabolic leaf springs is weight saving. For the same spring rate, they can achieve up to 30% weight reduction compared to conventional multi-leaf designs.

Advantages

-

Improved comfort and vehicle handling

-

Reduced unsprung mass and lower noise

-

Fewer parts, simpler design

Disadvantages

-

Not ideal for extreme overload conditions

-

Typically more expensive than conventional springs

Parabolic springs strike a balance between load-carrying ability and ride comfort, making them ideal for light to medium-duty applications and vehicles prioritizing fuel efficiency or payload optimization.

Z-springs (air links or lenker springs)

Z-springs are a variant of the parabolic spring, usually consisting of a single leaf with a characteristic "z" shape when viewed from the side. The spring is thick in the center and thin at both ends, following a parabolic thickness profile, but its geometry is designed to reduce lateral forces and improve axle alignment. This type of spring is used in combination with air suspension.

Key features

-

Lightweight and compact design

-

Optimized for specific axle configurations

-

Often found in trailer suspensions and some European commercial vehicles

Advantages

-

Space-saving layout

-

Improved directional stability

-

Lower manufacturing and assembly complexity

Disadvantages

-

Less common and harder to replace

-

Limited use cases outside specialized applications

-

Most expensive leaf spring to produce

Leaf springs with or without spring eyes

Not all leaf springs are designed the same. One of the key differences lies in whether the spring has spring eyes or not. Spring eyes are the looped ends of a leaf spring, allowing it to be attached directly to the vehicle chassis. However, in many heavy-duty applications, especially on trucks with multiple rear axles, leaf springs often do not have spring eyes at all.

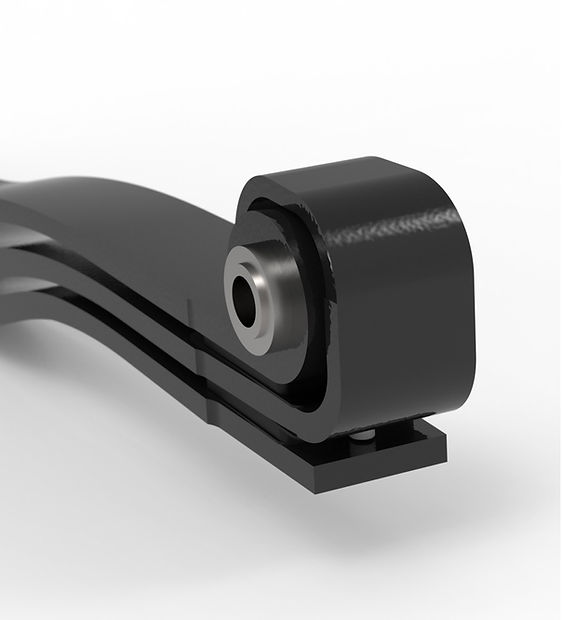

What is a spring eye?

A spring eye is the rolled or circular end of a leaf spring. It typically contains a bushing, allowing the spring to be fixed to the chassis via a bolt and either a rigid bracket or a flexible shackle. Spring eyes are critical for the proper connection and movement of the spring under load.

When do leaf springs have spring eyes?

Leaf springs include spring eyes when they serve as the main structural connection between the suspension and the vehicle chassis. These cases typically include:

-

Main leaf of a spring pack: in multi-leaf setups, the top (main) leaf usually has spring eyes at both ends

-

Mono-leaf springs: found in light-duty vehicles and some modern rear suspensions, these always include spring eyes

-

Front axle leaf springs: both ends are attached to the chassis, so spring eyes are essential

When do leaf springs not have spring eyes?

Some leaf springs are designed without spring eyes, and this is fully intentional. Common cases include:

-

Rear axle leaf springs on twin-axle (double wheel) trucks: In heavy-duty commercial trucks with a tandem axle configuration (two axles in the rear, also called double wheel axle setups), the leaf springs are often installed between the axles and do not attach directly to the chassis. These are known as link springs or floating leaf springs. They usually have no spring eyes, are mounted at both ends to swinging brackets or equalizer beams, are fixed in the center to the rear axle housing, and serve to distribute the load between the two axles.

These springs function as load-balancing elements, and because they are not connected directly to the chassis, they do not require spring eyes.

-

Helper or overload springs: These secondary springs, used to support high payloads, often sit on top of the main spring and are engaged only when needed. They don't need eyes because they are not fixed to the chassis.

The role of the spring eye wrap (wrap leaf) in leaf spring safety

Leaf springs are one of the most robust and time-tested suspension components used in commercial vehicles, trucks, trailers, and pickups. However, even the most durable main leaf can fail over time, especially near its spring eye, the most stressed and vulnerable point in the spring. To reduce the risk of a critical failure, many leaf spring designs include a wrap leaf, a simple yet highly effective safety feature.

What is a wrap leaf?

A wrap leaf (also called a safety leaf or spring wrap) is typically the second or third leaf in a multi-leaf spring pack. Unlike regular supporting leaves, the wrap leaf is extended forward to wrap around the spring eye of the main leaf. It does not connect to the chassis and it does not form an eye, but it overlaps the main leaf eye area to provide mechanical backup in the event of a failure.

How does it work when the main leaf breaks?

The most dangerous failure scenario in a leaf spring is when the main leaf breaks between the axle and the front spring eye. This can cause:

-

The axle to shift backward or sideways

-

Loss of alignment or vehicle control

-

Tension imbalance, increasing the risk of the other spring breaking

-

In extreme cases, separation of the axle from the chassis

When this happens, the wrap leaf keeps the spring eye section in place, acting as a secondary connection. It prevents the axle from detaching or moving out of alignment, allowing the driver to bring the vehicle to a safe stop without total suspension failure.

Without the wrap leaf, the suspension can collapse, and the vehicle could become unsteerable, especially dangerous under load or at high speed.

Where is the wrap leaf commonly used?

Wrap leaves are commonly used in:

-

Front axle springs in trucks, pickups, and vans

-

Any safety-critical suspension configuration where redundancy is needed

Contrary to common belief, wrap leaves are not limited to conventional multi-leaf springs. They are also used in:

-

Parabolic springs

-

Z-springs

-

Any type of leaf spring where failure of the main leaf could compromise vehicle safety

The use of a wrap leaf depends on the design goal, not the spring type. Manufacturers may add this feature to meet safety standards or customer requirements.

Is the wrap leaf always included?

No. Not all leaf springs include a wrap leaf. Lighter-duty applications, budget designs, or vehicles with alternative safety systems may omit the wrap. However, in many commercial vehicles, especially those operating under heavy load or long distances, the wrap leaf is a recommended or even required feature.

One-stage and two-stage leaf springs and the role of helper springs

Leaf springs are widely used in commercial vehicles, vans, pickups, trailers, and off-road equipment due to their simplicity and ability to handle high loads. However, not all leaf springs behave the same under varying loads. The way a spring reacts depends on whether it is a one-stage spring, a two-stage spring, or a system equipped with helper springs.

Each configuration is designed to balance ride comfort with load capacity, and understanding the difference helps fleet operators and vehicle owners choose the right suspension system for their needs.

What is a one-stage leaf spring?

A one-stage (or single-rate) leaf spring has a continuous load-deflection curve. This means that:

-

All spring leaves are in contact at all times

-

All leaves work together under both light and heavy loads

-

The spring stiffness (spring rate) is consistent across the full range of travel

Advantages:

-

Smoother ride when unloaded or lightly loaded

-

More even stress distribution

-

Simple and predictable spring behavior

Disadvantages:

-

Limited ability to handle very high loads without sacrificing comfort

-

Not ideal for vehicles that regularly switch between empty and fully loaded states

One-stage leaf springs are common in light-duty commercial vehicles or passenger vans where load conditions are fairly stable.

What is a two-stage leaf spring?

A two-stage (or dual-rate) leaf spring is designed to handle both light and heavy loads by using two distinct sets of leaves:

-

The main stage (primary spring pack) supports the vehicle under normal or light load

-

The secondary stage (additional leaves or overload leaves) only engages when the load reaches a specific threshold

This creates a progressive spring rate:

-

Softer under low load for better ride comfort

-

Stiffer under high load for improved load capacity and stability

Advantages:

-

Excellent for vehicles with varying payloads

-

Avoids harsh ride when empty and provides support when loaded

-

Better protection against bottoming out

Disadvantages:

-

More complex spring design

-

Potentially uneven wear between primary and secondary leaves

Two-stage leaf springs are widely used in medium and heavy-duty trucks, delivery vans, and utility vehicles.

What are helper springs?

Helper springs are separate spring elements added to support the main leaf spring system. They may be:

-

Additional leaf springs (mounted above or below the main spring pack)

-

Coil-over springs

-

Rubber or air springs that engage only under heavy load

Helper springs are typically not engaged during normal driving. They activate only when the main spring compresses beyond a certain point, providing extra support to prevent sagging or bottoming out.

Use cases:

-

Retrofitted to vehicles that experience occasional overloading

-

Commonly seen in pickup trucks, vans, and trailers

-

Useful when carrying cargo, towing, or adding weight temporarily

Advantages:

-

Cost-effective way to increase load capacity

-

Flexibility: comfort when empty, strength when loaded

-

No need to replace the entire spring system

Key takeaways

-

Conventional springs offer rugged durability for heavy-duty applications

-

Parabolic springs provide weight savings and improved comfort

-

Z-springs are specialized solutions for trailer and air suspension systems

-

Spring eyes are essential for chassis connection in most applications

-

Wrap leaves provide critical safety backup in case of main leaf failure

-

One-stage springs offer simplicity, two-stage springs offer versatility

-

Helper springs add load capacity without replacing the main suspension

Related topics

Continue learning - explore these related topics: